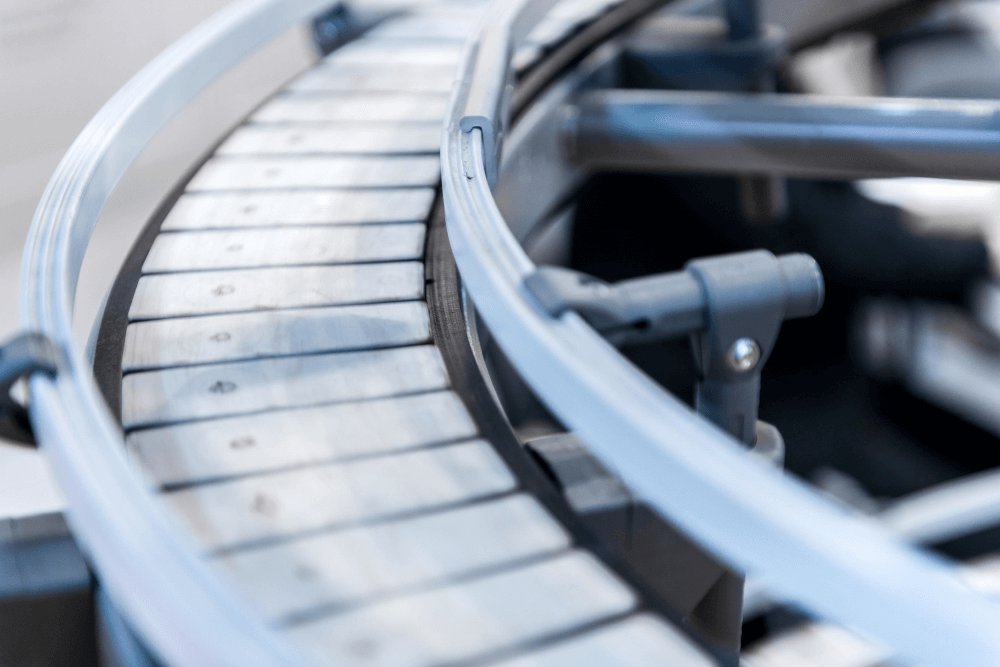

For businesses in the food industry, it’s essential to keep products safe and consistent while on the production line. That’s where conveyor belts come in handy – they move products along at a consistent pace, ensuring that they’re kept at a specified temperature. But even with conveyor belts working as they should, there are still risks associated with them. That’s why it’s so important to consider heat-resistance conveyor belts when making purchasing decisions.

Why Heat resistance conveyor belts are important

Heat resistance conveyor belts are important to any business because they can help protect delicate equipment and inventory from damage caused by intense heat. In particular, conveyor belts that are made out of heat-resistant material can withstand temperatures up to 1,000 degrees Fahrenheit. This is important because many industrial processes occur at high temperatures, and a damaged conveyor belt can contaminate the environment with potentially harmful chemicals and fumes. By using a heat-resistant belt, your business can reduce the risk of equipment failure and contamination while ensuring its operations remain efficient.

Benefits of Heat resistance conveyor Belts

Heat resistance conveyor belts are a critical part of your business. They help you move products more efficiently and keep your machines running at their peak performance. Conveyor belts also play a major role in production, so it’s important to get the right belt for your needs.

There are many benefits to using heat resistance conveyor belts:

They help keep your machines running at their best. If you have a slow or failing machine, adding a heat-resistant belt can help keep it running smoothly.

. If you have a slow or failing machine, adding a belt can help keep it running smoothly. They decrease product losses. A bad belt can cause products to jump off the belt and into the machinery; a heat-resistant belt helps protect these products from damage.

. A bad belt can cause products to jump off the belt and into the machinery; a heat-resistant belt helps protect these products from damage. They speed up production. When belts move faster, they reduce the time spent moving products around and contribute to faster production rates.

If you’re looking for an efficient way to move your products and improve production, consider using heat-resistance conveyor belts.

What a heat resistance belt is made of

Heat resistance conveyor belts are made of a variety of materials to best suit the needs of the business. Some common types of heat-resistant belts are Vinyl, Tyvek, Polyester, and Cordura.

Vinyl is probably the most common material for heat-resistant conveyor belts because it is both durable and affordable. It does not tend to stretch much, so it can handle high temperatures without breaking. However, vinyl belts do not conduct heat as well as other materials and should be used in environments where temperatures stay below 158 degrees Fahrenheit.

Tyvek is similar to vinyl in that it is durable and affordable but also conducts heat well. It also has a smooth surface that helps reduce friction, making it ideal for applications where slip is a concern. Tyvek belts should not be used in environments with temperatures above 167 degrees Fahrenheit.

Polyester is a better option than vinyl or Tyvek when temperatures go above 175 degrees Fahrenheit because it absorbs less heat than those materials. Polyester also has a more rubbery texture which makes it easier to move objects on the belt. Polyester belts should not be used in environments with temperatures above 194 degrees Fahrenheit due to their susceptibility to fire.

Cordura is a popular choice for military applications because it is extremely tough and resists wear and tear. Cordura belts are not as durable as other materials but they are more expensive so they are usually found only in higher-end businesses. Cord-era belts are not recommended for use in environments with temperatures above 194 degrees Fahrenheit.

Types of activities heat resistance belts can resist

Heat resistance belts are perfect for businesses that require a high degree of protection from heat. Some types of activities that heat resistance belts can resist include: welding, cutting, and heavy manual labor.

These belts provide a high level of protection from exposure to extreme heat and temperatures. They are commonly used in the manufacturing and construction industries where exposure to high heat is common.

Herniated Disc Syndrome (HDS) is a condition that affects the spinal cord and can be caused by intense physical or non-physical forces on the spine. One such force is exposure to extreme temperatures.

The National Institute for Occupational Safety and Health (NIOSH) states that workers who are exposed to elevated temperatures for extended periods are at an increased risk for developing HDS. NIOSH has identified welding as one of the most dangerous occupations in terms of occupation-related HDS cases. Welders are especially at risk because they often have to work near heated metal objects, which can cause permanent damage to their spines if not properly protected.

There are many benefits associated with using heat-resistant belts in the workplace. Not only do they protect workers from injury, but they also improve worker productivity by reducing the amount of time spent on tasks that would normally require protective gear.

Preventing unwanted wear and tear while engaging in activities

Preventing unwanted wear and tear while engaging in activities can be done by using heat resistance conveyor belts. These belts help to move materials at a consistent speed, preventing them from becoming damaged or wrinkled due to the forces of friction. Additionally, these belts can be customized to fit any specific need, ensuring that your business is getting the most out of its conveyor belt system.